Products

RSW system

RSW – Refrigerated Sea Water

- Ideal for pelagic (purse seining and mid-water trawling)

- Enables preservation of large catches, by cooling the catch rapidly to a temperature that allows storage on board over time, without significant reduction in quality

- Has enabled large quality of mackerel, horse mackerel and herring to be used for human consumption

- Improves quality on fishmeal by better rawmaterial

- Reduced quotas set higher standards – better product means better price

For further information about RSW systems, please contact us here.

Product Description

Teknotherm RSW-system

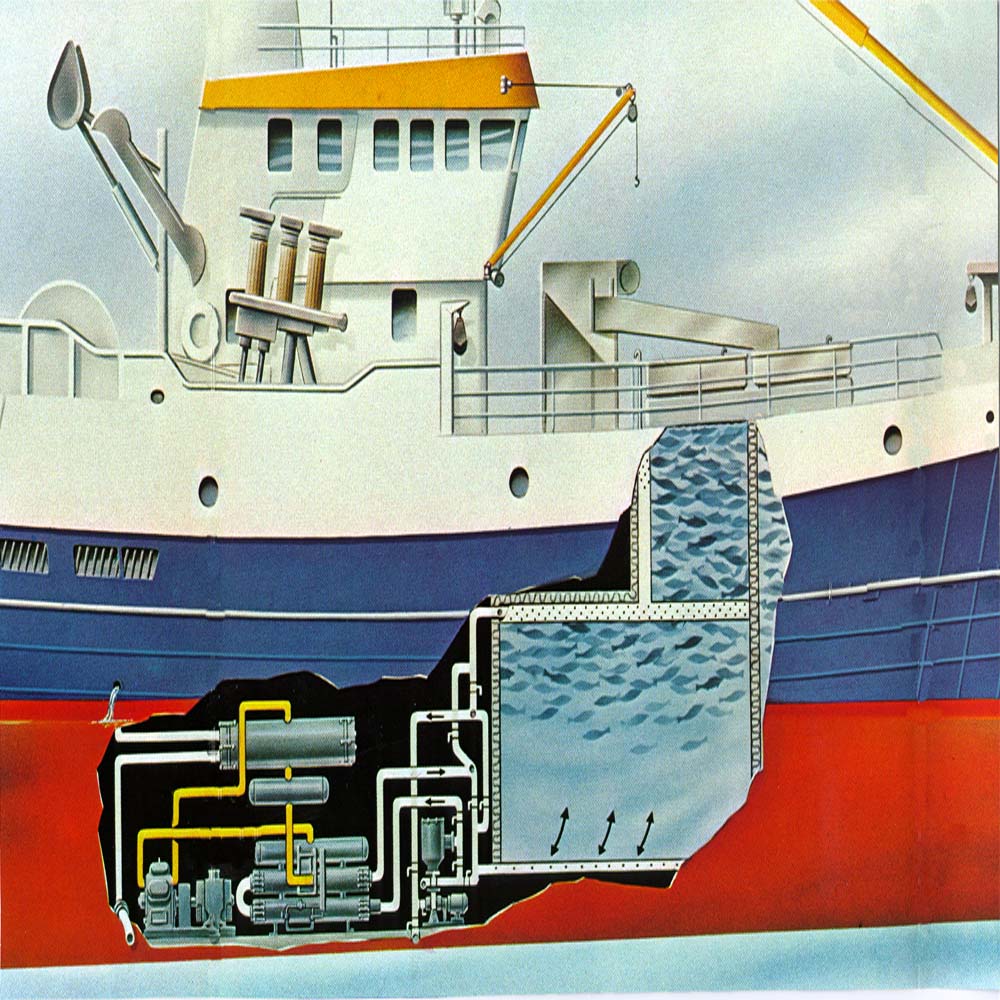

Teknotherm RSW plants mean rapid chill-down and storage of the catch in Refrigerated Sea Water. Storing the catch in RSW is an effective and cost-saving method of preserving the catch until landing ashore or further processing on board. The catch is brought down close to the freezing point of sea-water in a minimum time by Teknotherm`s highly efficient RSW-chillers of flooded shell & tube type.

The RSW-principle

In simple terms, a RSW-system functions as follows: Seawater is recirculated by pumps through the tanks (therefore product) and the chilling system. The seawater is chilled by the refrigeration

machinery before it enters the tanks in the bottom and is distributed evenly over the complete

bottom cross-section of the tanks through a set of perforated plates or similar distribution devices.

The chilled seawater passes upwards through the tank and layers of fish, thus keeping the fish semi-floating (in suspense) and at the same time cooling it. The water returns through suction screens in the top of the tanks to the chilling unit of the system, passing through this and repeating the circulation process through the system. To keep the circulating water in good condition, a limited amount of feedwater may be added, and “dirty” water bled off.

The water circulating system is arranged as such that the flow can be reversed by the operating certain valves in the main water distribution manifold.

The storage tanks

The RSW tanks are normally constructed side by side to cover the width (beam) of the vessel. There are usually 3, 6, 9 etc. storage tanks. The storage tanks are normally loaded to a capacity of approximately 80% fish and 20% water, depending on type of fish. The tanks must be properly insulated from the hull, deckheads, machinery- and accommodation spaces to limit the possibility of heat ingress as far as

possible. The tanks must further be equipped with over-flow and equalizing pipes. It is essential that the interior surfaces of the tanks have a smooth finish, with no obstructions or sharp edges.

Flexible refrigeration installations

The necessary machinery, including chillers, compressors, receivers condensers and pumps, can either be installed as one or several self-contained unit(s) or as individual and separate components.

The machinery can be placed according to individual needs; in the engine room, a dedicated

refrigeration compartment, under the shelterdeck or in the bow of the vessel, or anywhere else where practical on board. The pumps however, should be situated as low as possible.

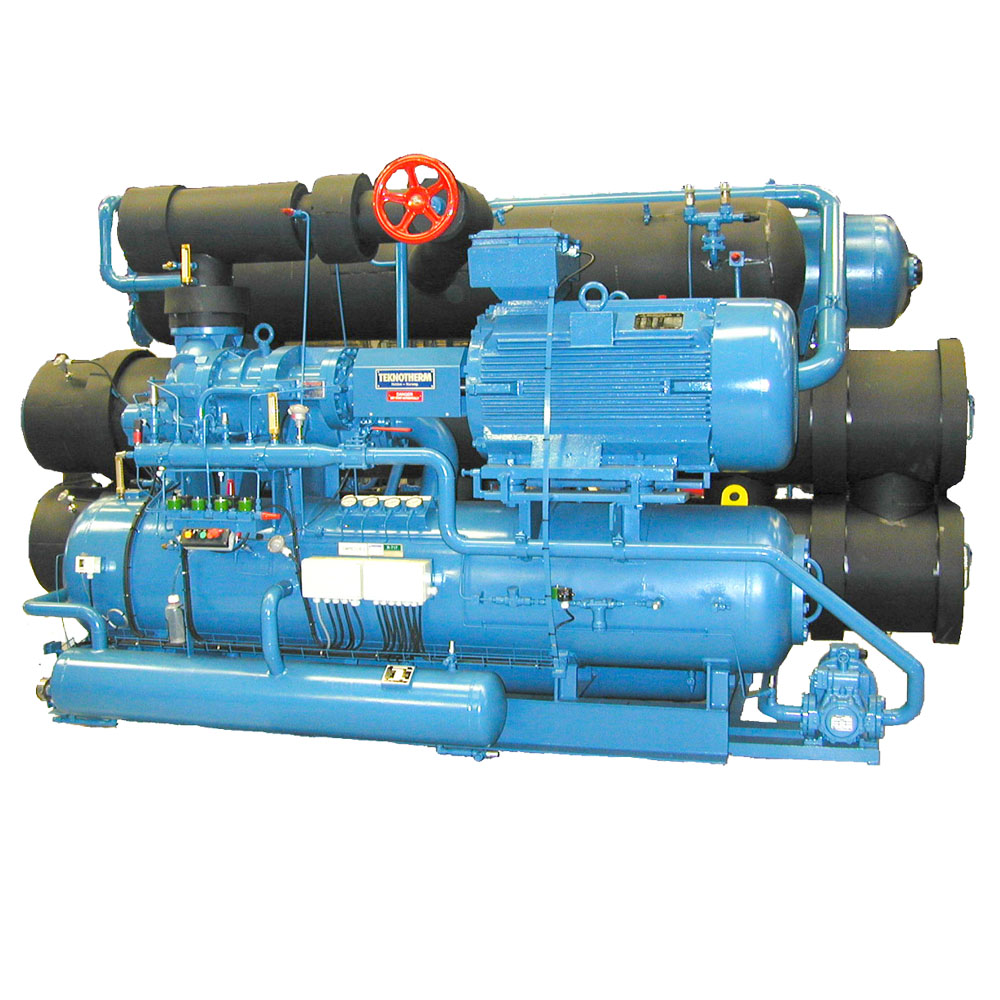

The refrigeration machinery

The machinery will include heavy duty compressors of either reciprocating- or screwtype. The condenser(s) may be of shell & tube- or platetype. The RSW-chiller will be constructed as a flooded shell & tube type evaporator, i.e. seawater to be cooled, will be passing inside the innertubes while the refrigerant is evaporating on the outside side (shell side) of the tubes, thereby cooling the seawater.

The electric panel will include motor starters of various type according to customers request, and the controls will either be of the traditional electromechanical type or the up to date PLC type with all vital parameters and functions shown on LCD display.

The water pumps for condenser cooling- and RSW-circulation system are included as standard items,

of end-suction design or according to customers request for special design and materials. Drives can be either electric or hydraulic.

Teknotherm refrigeration equipment can be supplied with class- or works in-house certification.

Teknotherm RSW-plant can be supplied to operate on various types of refrigerants of the most modern halocarbon type or ammonia.