Products

Screw compressor

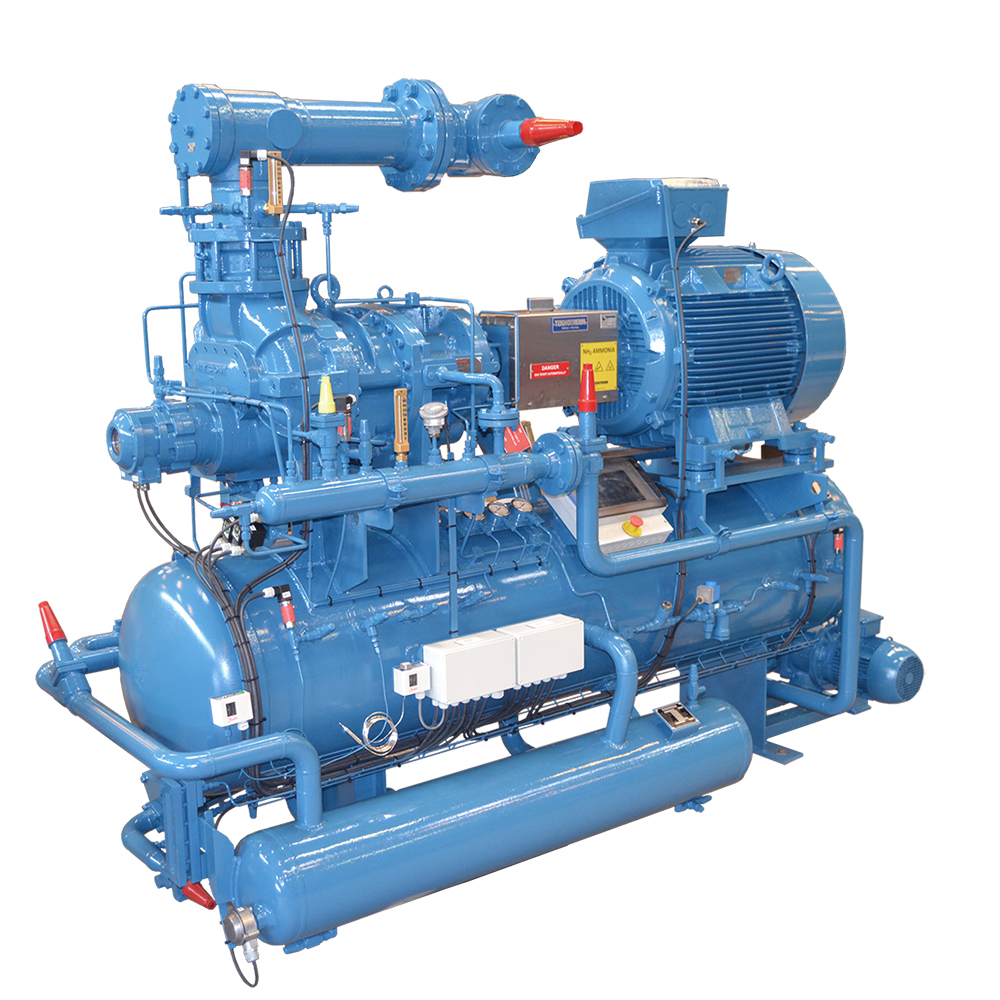

The compressor unit is specially designed for marine application. Components and materials are chosen with reference to long experience in marine refrigeration. Special care has been given to dimensions, weights and easy maintenance. Suitable for all common refrigerants.

The unit is, as standard, delivered complete assembled with compressor, motor, oilcooler, oil pump, oil filter, suction strainer, check valves etc. Further is provided gauge-panel with safety devices for pressure and temperatures. The unit has internal oilpiping and el.wiring. The units can be delivered in a number of variants.

For further information about Screw compressors, please contact us here.

Product Description

The screw compressor, of Mycom make, is a positive displacement rotary machine having two rotors – male and female, made of special forged steel, mounted in a casing of high grade cast iron. The main bearing are sleeve type lined with metal. The balance piston practically eliminates thrust on the bearing, resulting in long service. The compressor has built-in capacity control by 100-10% by stepless slide valve mechanism, and manual adjustable volumetric ratio.

The oil separator is of two stage type with special coalescing elements, effectively separating oil from the discharge gas.

The oil cooler is as standard of shell & tube type. Either in seawater cooled execution or of thermosyphon type. Oil cooling by refrigerant injection is also available.

Oil temperature will be kept stable by thermostatic controllers.

The oil pump is a highly efficient gear type with double helical gears and built-in relief valve.

The electric control panel is fully PLC based, consists of necessary control, protection and safety devices and automatic capacity control. All circuits are interlocked to protect the system from malfunction.

The panel contains automatic capacity controller and current limiter function, run time indicator, ampermeters and pilot lights. The control panel to be either built-on the unit, or supplied separately.